Dr Milan Nedeljković, member of the board of management of BMW AG, responsible for production (right) and Hans-Peter Kemser, head of BMW Group Plant Debrecen.

Image: Supplied

BMW has entered a new chapter in its production story with the opening of its state-of-the-art facility in Debrecen, Hungary.

More than just another plant, the site represents the physical embodiment of BMW’s iFactory philosophy - lean, green, digital and human-centred.

The Debrecen facility not only extends the company’s global production network but also signals a bold new era for how premium cars are conceived, built and delivered.

Dr Milan Nedeljković, member of the board of management of BMW AG responsible for production, emphasised the scale of BMW’s global operations. “We now have 32 plants across four continents with more than 80,000 associates,” he explained.

“Together they built more than two and a half million vehicles last year.”

The network extends far beyond assembly lines. It includes a supply chain of more than 2,500 suppliers delivering over 30 million parts every day.

But, as Nedeljković stressed, this is far more than a logistical web. “It’s a holistic network, based on trust, competence and agility, one unit, irrespective of where you are. And it has been built on principles that have grown over decades.”

Among those principles, flexibility and resilience stand out as crucial to the company’s success.

For BMW, flexibility is not a corporate slogan but a deeply embedded way of working. Plants are designed to be structurally adaptable, enabling expansion without disruption.

“Take the example of assembly with a finger building structure,” Nedeljković explained. “It allows us to extend production by simply lengthening the ‘finger’ without altering the main production flow.”

Technological flexibility is just as vital. Machinery at BMW plants can handle different models and drivetrains on a single line. IT systems allow rapid responses to changes in demand or supply. Most impressively, production sequences can be altered just six days before a vehicle is built.

This agility proved invaluable during the recent semiconductor shortages. “We were capable of changing our sequence, building other cars until the chips arrived,” he said. “That capability is deeply rooted in our structures.”

BMW's new iFactory Debrecen plant in Hungary is BMW’s first fossil fuel-free plant with a solar park covering half a million square metres powering the site.

Image: Supplied

Another strand of BMW’s production philosophy is what it calls “balanced value creation” - knowing where to develop in-house expertise and where to rely on suppliers. The best example is the battery cell.

“It was clear from the beginning that if we are moving towards electromobility, we must understand the battery in depth.

“That’s why, 20 years ago, our labs began designing the content of a battery. Today, we have a Battery Competence Centre in Munich with hundreds of people working on technology, and we also operate a manufacturing competence centre to perfect production methods.”

Yet BMW has chosen not to manufacture cells itself. “Technology evolves too quickly,” he said. “We need to offer customers the best state-of-the-art battery, which means working with suppliers while retaining deep knowledge ourselves.”

Premium brands must deliver choice, and BMW is no exception. Customers expect highly individualised vehicles. But Nedeljković says variety risks creating chaos in production. “Complexity is no good for manufacturing, yet we must provide the customer with his individual car. Our system is built to manage variants intelligently and efficiently.”

This balancing act - personalisation without inefficiency - has become one of BMW’s defining capabilities, he says.

The new Debrecen facility is built entirely around BMW’s iFactory framework, which rests on four pillars: lean, sustainable, digital and people-focused. For Nedeljković, these are more than buzzwords. “They are the core principles that define our factories,” he said.

Lean processes mean minimal waste and seamless flows. Sustainability commits BMW to eliminating fossil fuels from production. Digitalisation underpins both efficiency and quality.

And people - the associates themselves - remain the foundation on which everything else rests.

Hans-Peter Kemser, head of BMW Group Plant Debrecen, explained how these principles were translated into reality.

“With the Neue Klasse, production was on the table from the start,” he said. “Product and production were developed together. We constantly asked how to simplify, how to improve and how to make things better.”

This close integration allowed engineers and developers to anticipate challenges before they arose. It also ensured the plant could support the advanced technologies underpinning the Neue Klasse.

One of the most striking aspects of Debrecen is how much of it was created in the digital world before physical construction. “In the early days, the site was just 400 hectares of green land, but in virtual reality, we already had robots moving, lines running, and processes simulated.”

The team even developed what they called a “ghost car”- a fully simulated production flow without a physical vehicle present. “You stood there with robots moving and thought, where’s the car? But we were testing every system, every supplier connection, every data stream,” he said.

Digitalisation doesn’t stop at planning. Every associate in Debrecen works with a mobile phone, used for training, communication and process updates.

“It means there are no information boundaries,” Kemser explained. “I can send a message to every associate instantly. Everyone has the same information at the same time.”

Hundreds of associates from Germany, Mexico, China and elsewhere came to Hungary to support the plant’s launch.

Image: Supplied

Debrecen is BMW’s first fossil fuel-free plant. A solar park covering half a million square metres powers the site, supported by innovative energy storage and high-tech heating systems. Most significantly, the facility houses the world’s first fully electric automotive paint shop.

The commitment extends beyond energy. Water management is carefully planned, biodiversity is encouraged with green spaces, and more than 10,000 trees will be planted on the site.

“This plant is not just an industrial facility,” Kemser said. “It’s part of the landscape. We even plan for sheep and bees to share the grounds with us.”

Another major focus was on reducing product complexity wherever possible.

“When I started nearly 30 years ago, I worked on wiring harnesses. They were heavy, complicated bundles that had to be fitted in seconds. Here, we redesigned the system. We took 600 metres of wiring out and reduced the weight. The front end now has one-third fewer parts. These changes make a big difference.”

By building flexibility into the body shop and assembly lines, the plant is prepared for future models and technologies without unnecessary complexity today.

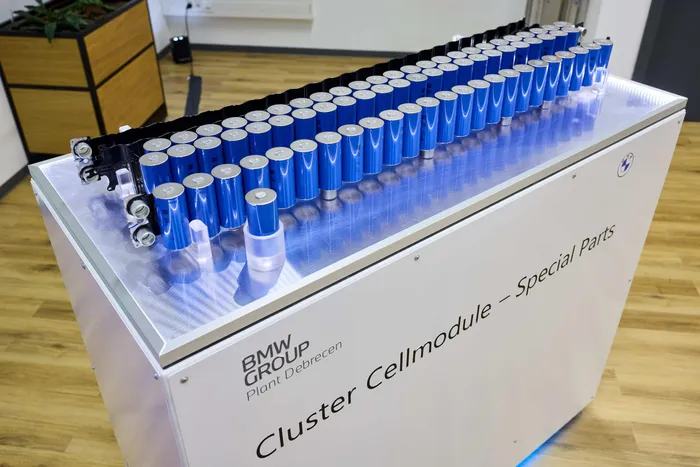

BMW's new battery cell powering their Neue Klasse vehicles.

Image: Supplied

For both executives, people remain the ultimate differentiator. BMW’s global network means that expertise is constantly shared. Hundreds of associates from Germany, Mexico, China and elsewhere came to Hungary to support the plant’s launch before returning home with valuable experience.

“It’s based on a strong team,” Nedeljković said. “Expertise and know-how are crucial, but culture is even more important - shared values, respect and responsibility.”

Kemser agreed: “What is a plant leader without people? Nothing. Our culture is about subsidiarity - your process, your responsibility. If there’s a problem, we solve it together. With more than 50 nations working here, you cannot tell who comes from where. It’s one BMW culture.”

As production of the Neue Klasse gets underway, both men are clear that Debrecen is more than just another factory. It represents the living reality of the iFactory philosophy and a signal to the wider industry.

“Wherever you walk in Debrecen, you can see the BMW iFactory come to life: lean, sustainable, digital,” Kemser concluded. “This is not just a new plant. After nearly three decades at BMW, I can say with confidence: this is the beginning of a new era.”

Related Topics: